Fountain ؘ– the first highly durable AR-coated glass offered by AGCULTURE™

AGCULTURE™, a new business activity of AGC Glass Europe, is launching its first durable glass product, Fountain, which has been specially designed to improve crop yields for horticultural growers. Fountain is basically a low-iron float glass, one side of which is treated by a chemical reaction to create the required level of light diffusion. This is sandwiched between two durable anti-reflective (AR) coatings. The side of the glass with the microstructures is positioned on the inside of the greenhouse, while the flat side is positioned on the outside. Despite this simple design, Fountain differs in several key ways compared to existing solutions on the market.

High hemispherical transmission for increased crop yield

The double-sided AR coating combined with low-iron float glass provides a high level – around 96.5% – of photosynthetically active radiation (PAR) transmission, regardless of the level of diffusion. However, the sun’s position changes throughout the day and direct PAR transmission (perpendicular to glass surface) alone cannot sufficiently guide growers as to which type of glass to use in order to maximise the amount of light in their greenhouses. Hence, according to NEN2675 + C1:2018, a more meaningful parameter is to consider hemispherical transmission, which is the integral value of light transmission for all angles of incidence. As a rule of thumb defined by Wageningen University & Research (WUR) for tomatoes, a 1% increase in hemispherical transmission equals a 0.8% increase in crop yield1. Depending on diffusion level, the hemispherical transmission delivered by Fountain glass ranges from 85.5% to 80.6%.

UV transmission – a critical point for pollination and colour formation

The low-iron glass used in Fountain offers minimum absorption in the UV range and – when equipped with double AR – delivers 89.5% UV transmission. This high level of UV transmission is very important to the pollination process since part of the bumble bee’s eye sensitivity lies in the middle of the UV range (340 nm) and high transmission in this range helps bees to find their way, thus enhancing the pollination process. Moreover, with the emergence of lettuce growing in, for example, the United States, UV light plays a significant role in the colour formation of such crops as Lollo Rossa.

Hortiscatter as a defining factor in higher yields

The outer leaves of crop canopies typically block light from reaching deep inside the canopy, meaning inner leaves receive less light and can contribute much less to the photosynthesis process, resulting in lower yields. Moreover, intense direct light causes leaves to bend down in order to protect themselves, reducing the effective leaf area receiving light, which in turn reduces the photosynthesis rate and productivity. The microstructure of the inner side of Fountain glass can provide a wide range of hortiscatter from 15% to 63%. This high level of hortiscatter is basically a sign of homogeneous distribution of light, which can penetrate deep inside the crop canopy and increase the photosynthesis rate and productivity by enabling the inner leaves to contribute. Furthermore, having homogeneous and uniform light inside the greenhouse causes the leaves to experience less stress, so they tend to orient themselves more horizontally. This effect not only enables light to penetrate more deeply into the canopy but also increases the effective area of each leaf, contributing to the photosynthesis process which in turn results in higher productivity. WUR has identified an empirical rule for tomatoes: a 1% increase in hortiscatter can represent a 0.3% increase in yield2. Considering the wide range of hortiscatter provided by Fountain, growers can significantly improve their output by using this glass.

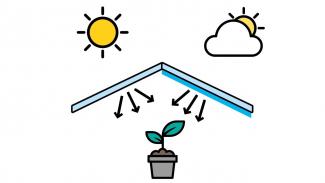

Hydrophilicity adapts to various weather conditions

Combining the inner microstructure of Fountain with the AR coating results in the inner surface becoming hydrophilic, an essential characteristic if condensation occurs. Non-hydrophilic glasses can cause dripping inside the greenhouse, damaging crops and leaves and increasing the chance of disease formation. Moreover, if condensation takes the form of droplets, then those droplets can reflect light, thus reducing the amount of light entering the greenhouse. Condensation on Fountain glass occurs as a continuous water film which results in greater glass transparency in wet condition, i.e. an increase in hemispherical transmission of up to 1.4%. On a sunny day, the glass temperature is high and the greenhouse is subject to too much direct light. As a result, no condensation occurs and the level of diffusion is high. On a cold or cloudy day, the glass temperature is low, leading to condensation. This is when growers need more direct light to enter in order to improve solar heat gain. Basically, there is no need for high light diffusion since the clouds are already diffusing the light. In other words, Fountain’s smart action depends on the situation of the sky.

Easy to clean

The surface of Fountain glass is structured on one side (the inner side is chemically etched), while the outer side is similar to normal flat glass. Shading systems and cleaning procedures applied by growers cannot damage the glass or cause any difficulties for growers.

Durability measured over the total lifecycle of the greenhouse

A greenhouse is built with an expected life span of more than 20 years, but today the focus is on the selected glass’ day-zero performance instead of over the entire lifecycle of the greenhouse. Greenhouse glass is subject to recurrent cleaning by growers, either by brush cleaning machines on the outer surface, or by pressurised water on the inner surface (typically once a year). Since maximising the amount of light can significantly increase crop yields, AR-coated glass is a reasonable solution for growers. However, in recent years, many growers have noted that after a few years the AR effect disappears. This has convinced them to stop opting for AR-coated glass since it was not a mechanically durable solution. On the other hand, unprotected AR-treated glass (AR by acid etching) can also suffer from corrosion, due to the fact that when bare glass comes into contact with moisture, volatile elements such as Na and Ca can emerge from inside the glass. These elements will react with the water and form a basic environment that results in glass corrosion (this effect is mainly seen in shower glass). Since condensation occurs frequently on greenhouses, the unprotected AR-treated surfaces can suffer from corrosion even faster due to the lack of chemical durability. Fountain has been designed to be the most durable product capable of resisting most of these challenges. Firstly, the AR coating used in Fountain is a hard coating (certified Class A under standard EN1096), meaning it will withstand brush cleaning and ensure the maximum lifetime of the AR effect. Secondly, the AR coatings on both sides of the glass act as a diffusion barrier to the volatile elements. In addition, applying and removing whitewashing on the AR coating will not cause any damage to the coating, meaning that growers can enjoy the high-performance AR effect for most of the greenhouse lifecycle.

More info on Fountain advanced greenhouse glass on www.agculture.eu

[1] Marcelis, L.F.M., Broekhuijsen, A.G.M., Meinen, E., Nijs, E.M.F.M. and Raaphorst, M.G.M. 2006. Quantification of the growth response to light quality of greenhouse grown crops. Acta Horticulturae 711, 97–104. doi:10.17660/ ActaHortic.2006.711.9.

[2] Li, T., Heuvelink, E., Dueck, T.A., Janse, J., Gort, G. and Marcelis, L.F.M., 2014. Enhancement of crop photosynthesis by diffuse light: quantifying the contributing factors. Ann. Bot. 114, 145-156.

Share this page

AGCULTURE™

Mohammad Shayesteh

mohammad.shayesteh@agc.com

www.agculture.eu

AGC Glass Europe, a European leader in flat glass

AGC Glass Europe produces, processes and markets flat glass for the construction industry (external glazing and interior decoration), car manufacture and other industrial sectors (transport, solar power and high-tech). It is the European branch of AGC, a world leader in flat glass. It has over 100 sites throughout Europe and employs around 13,000 employees.

More information on www.agc-glass.eu (corporate site), www.agc-yourglass.com (glass for the construction industry) and www.agc-automotive.com (for the automotive industry).

About AGCULTURE™

With a view to meeting the global need for sustainable and efficient food production in ever-increasing quantities, AGCULTURE™ is taking a major step forward in providing highly sustainable, technology-driven solutions for the horticulture market. AGCULTURE™ - a new commercial arm of a leading flat glass company, AGC Glass Europe - was created in 2019 to leverage its technological and manufacturing capabilities to offer solutions specifically designed to help horticulturists. These solutions aim to make production healthier and increase yield, while reducing the use of carbon-based energy resources. More information on www.agculture.eu