The Volta project at a glance

Video with Marc Foguenne, VP Sustainability at AGC Glass Europe and responsible for the Volta Project. During this interview he explains more about the project, covering the context, objectives, technical solutions and the ongoing cold repair.

Can you describe this new technological design and the expected carbon savings?

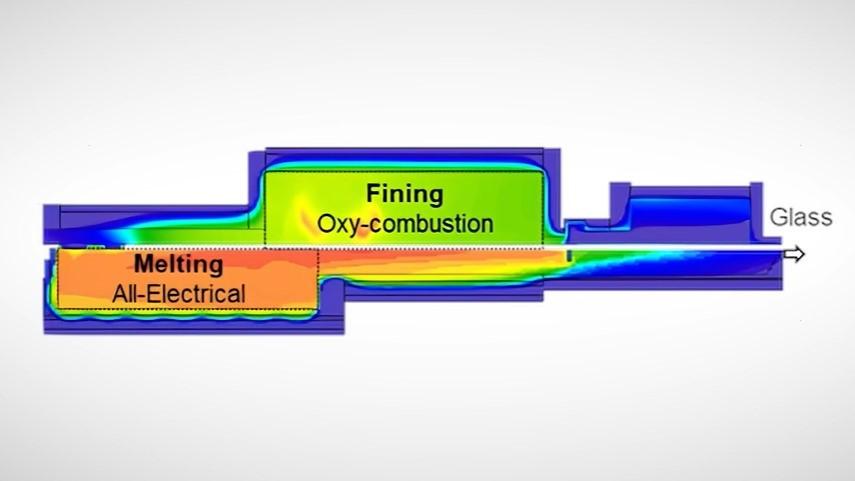

The new design is invented through a partnership with Saint-Gobain in AGC's existing patterned glass furnace in Barevka (Czech Republic). Once entirely refurbished, the production line will be 50% electrified and 50% fired by a combination of oxygen and gas, while industry standard is close to 100% natural gas. Material consumption will be strongly reduced thanks to a high ratio of recycling. These are two technical breakthroughs compared to current technology used in flat glass furnaces.

The hybrid furnace is expected to reduce the furnace's energy-related emissions (scope 1 and 3) by 75%, a reduction of over 193,000 tonnes CO2 equivalent over the first ten years of operation. The full plant will be supplied with green electricity, as well.

Photo: schematical view - not the actual design

What can we expect of this technology in terms of circularity and standards?

Before we will be able to engineer electric melting technology, the old patterned glass furnace on the site of Barevka in the Czech Republic was stopped for what we call the “Cold Repair”. That means that the furnace is cooled down and brought to a full stop. Than the refurbished works will pave the way to the conversion of this production line. This next phase is expected to be implemented and the new furnace ready for operational success by early 2025.

Besides the lowest carbon emissions possible, the refurbished plant will also reach the highest standards in terms of safety, environment (NOx, SOx), energy consumption and quality. The focus is also put on circularity as the new line will operate at a high ratio of recycled materials, much higher than the industry standards. This will be the flat glass production line having the lowest emissions possible combined with the highest recycled material level.

It will be the most sustainable flat glass line design contributing to both companies’ paths towards carbon neutrality and to the necessary acceleration of the flat glass industry’s decarbonization.

Further details on the Volta project’s webpage

The "Volta" R&D project is funded by the Innovation Fund of the European Union*.

(*) Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or the European Climate, Infrastructure and Environment Executive Agency (CINEA). Neither the European Union nor the granting authority can be held responsible for them.