The major environmental impact of glass production is caused by atmospheric emissions from melting activities.

- The combustion of natural gas and the decomposition of raw materials during the melting leads to the emission of CO2. Beside water vapour, this is the only greenhouse gas emitted during the glass production.

- Sulphur dioxide (SO2) from decomposition of sulphate in the batch materials can contribute to acidification.

- Nitrogen oxides (NOx) due to the high melting temperatures, and in some cases due to decomposition of nitrogen compounds in the batch materials, also contribute to acidification and formation of smog.

- Evaporation from the molten glass and raw materials can cause a release of particles into the atmosphere.

CO2 emissions

A continuous decrease of specific energy required to melt glass

Practically most of the direct CO2 emissions in AGC Glass Europe comes from melting activities. Some 75% of the CO2 emissions from the furnaces are energy-related, with the remaining 25% caused by decomposition of raw materials.

A reduction of 30% in direct emissions in the last 30 years

Furthermore, watching only the last 30 years, our direct emissions decreased by around 30% between 1990 and 2020. This reduction was the result of the combined effect of improvements in furnace's efficiency and the replacement of heavy oil by less impactful natural gas. Recycling of cullet also helped to reduce CO2 emissions by saving raw materials and energy for melting. Roughly speaking, an additional 10% of melted glass coming from cullet will allow to decrease melting energy by 2%

The challenge of reducing another 30% direct emissions by 2030

While these historical factors attest to the feasibility of the 2030 objectives set within the glass industry, they also show the difficulty of achieving them. The 30% decrease must be achieved not in 30 years but in less than a decade. Moreover, this involves not only direct emissions but all embodied carbon, and lastly, previous approaches can no longer be used, since glass melting furnace are now all powered by natural gas. Incremental improvements in furnace efficiency are no longer possible; instead, technological breakthroughs are needed.

Fig. 6 shows that the specific energy required to melt 1 tonne of flat glass is close to 100 GJ (between 2019 and 2023).This improvement is quite outstanding compared to 1880, as the specific energy used was 10 times higher, but it the yearly gains are now marginal if any, confirming the need of technological breakthrough to reach our decarbonization target and intermediate milestone.

Required breakthrough technologies

One of the most promising furnaces is powered by a unique system called ‘hot oxycombustion’, using oxygen for combustion instead of air and reuses heat from flue gases to preheat the natural gas before it is injected into the furnace. The furnace in Boussois (France) was the first float furnace in Europe to operate fully on the hot oxycombustion process and the first in the world to have the natural gas and oxygen preheated. This furnace has proven to be the most ecological float furnace in the world.

Another very promising technology that requires also technological breakthrough is electro-melting. While limited percentage of electrical melting is not new (generally called electro-boosting), a significant percentage of melting energy from electricity cannot be reached today because of the strict quality requirements for float, and such a progress requires a major technological breakthrough. AGC and Saint-Gobain have announced in February 2023 they will be collaborating on a project to this end (read press release).

AGC’s patterned glass production line in Barevka, Czech Republic, will be entirely refurbished into a high performing & state-of-the-art line that targets to be 50% electrified and 50% fired by a combination of oxygen and gas. This is a technical breakthrough compared to current technology used in flat glass furnaces fired by natural gas. It will be the most sustainable flat glass line design contributing to both companies’ paths towards carbon neutrality and to the necessary acceleration of the flat glass industry decarbonization.

Use of Hydrogen in substitution of natural gas, carbon capture and storage or use (CCS/CCU) are other potential technics which require technological breakthroughs and which are currently evaluated or tested.

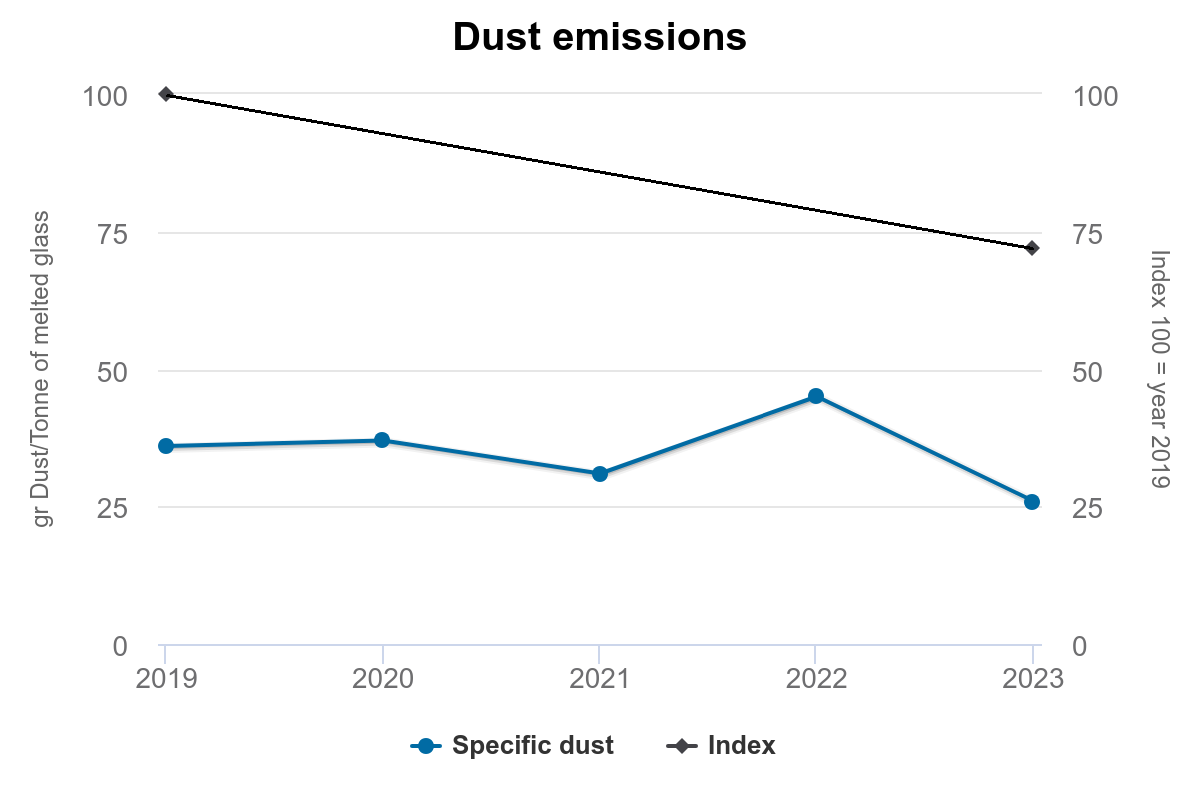

Other air emissions

As already mentioned, a main environmental objective is to further reduce emissions of dust, acidifying pollutants, and CO2. Tackling these in an integrated way is a complex matter, as most reduction technologies have disadvantages as well as advantages in terms of efficiency, glass quality, yield, cross-media effects etc.

Under the terms of the Industrial Emissions Directive (IED 2010/75/EU) a current valid Glass BAT (Best Available Techniques) reference document has been published (2012/134/EU March 2012). This document describes the environmental techniques applicable to the glass industry together with their advantages and disadvantages and associated emission limit values. These will be revised following the recent revision or the Industrial Emissions Directive and the coming revision of the Glass BAT Reference Document. See https://eippcb.jrc.ec.europa.eu/reference/manufacture-glass-0

Air pollution control units to reduce specific emissions of SOx and NOx

AGC Glass Europe has systematically installed an Air Pollution Control (APC) unit on each of its float lines. Generally, to comply with the IED Directive and the local legislation derived from it, the main solution chosen is to install Air Pollution Control units, together with a set of primary measures. These units are made up of a DeSOx system to abate the dust and acid components, and/or a DeNOx system to reduce the NOx, depending on the level of reduction required.

Fig. 9 shows the specific emissions of SOx and NOx (expressed in kg of pollutant emitted in the air/tonne of glass) since 2019 for Upstream Operations. Thanks to the installation of DeSOx and DeNOx systems in our group, together with improvements in technology and more careful selection of our raw materials, specific emissions of SOx and NOx are now a fraction of levels obtained before implementation of these actions.

The DeNOx process is based on the Selective Catalytic Reduction (SCR) system. Ammonia is injected into the flue gases and in contact with the catalyst it reacts with the NOx to give N2 and H2O, both naturally present in air. The aim of AGC Glass Europe was again to be proactive in this area, therefore the Group has already installed ten catalyst based DeNOx systems. Continuous improvements have contributed since 2019 to further decrease of NOx emissions.

Recycling DeSOx waste as raw material

The DeSOx not only reduces air emissions but also produces large quantities of by-products, mainly sulphates, resulting from desulphurisation of the flue gas. To avoid transferring, the pollution from the air to landfill, AGC Glass Europe favours recycling these sulphates wherever possible as raw material for the glass production. This requires continuous efforts and gave substantial results. Considering only the last five last years ;

More on our decarbonisation journey

Our carbon footprint

As part of AGC Glass Europe’s strategy and its environmental target for 2030, the carbon footprint is assessed on a yearly basis. By following the main principles and the standardized framework of the Green House Gas Protocol, we report and account for our corporate GHG emissions across our entire value chain.